Samarium Cobalt Magnets - Coatings And Adhesives

COATINGS

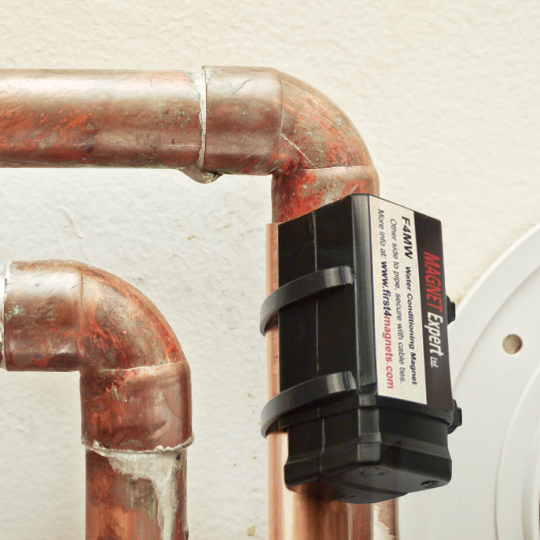

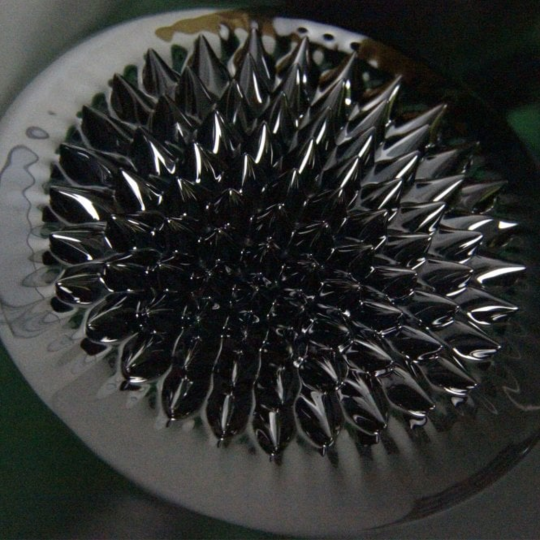

Typically samarium cobalt magnets do not require any coating or plating. That is because, unlike neodymium magnets, they contain little or no iron and therefore they have excellent resistance to corrosion. Some grades that are part of the Sm2Co17 family due contain iron but providing they aren’t exposed directly to water they will have a good resistance to corrosion.

When a coating is required, for marine applications for example, a typical coating is nickel-copper-nickel, much like neodymium magnets.

Other possible coatings include nickel, if the magnet is likely to be soldered to a circuit board, or resin if sterility is an issue, for example in medical applications.

If the magnet is to be used in acidic conditions it is recommended that the magnet is coated.

ADHESIVES

With the right adhesive, magnetic and non-magnetic material can be stuck to other surfaces. Clean and grease free services provide best bonding surface. At first4magnets.com we recommend the following adhesives for use with our neodymium magnets.

- Araldite Rapid Adhesive

- Loctite Industrial Strength Adhesive