In today’s modern age, it is becoming increasingly common to find magnets in most (if not all) manufacturing processes across the world. Magnets allow manufacturers to carry out various tasks that are too detailed or costly for a human workforce to undertake.

Nick got in touch to tell us just how he used magnets in his company’s manufacturing process.

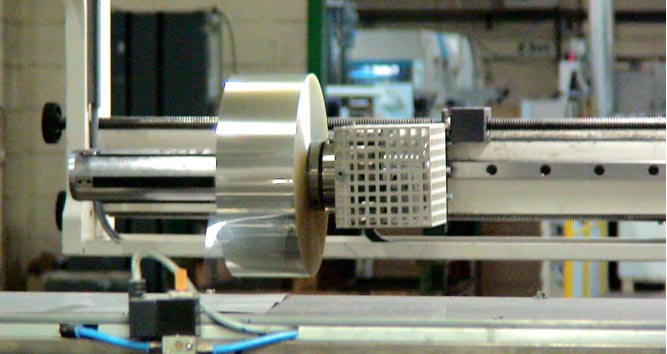

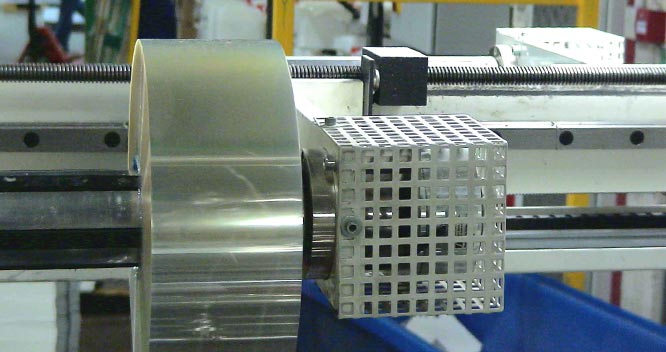

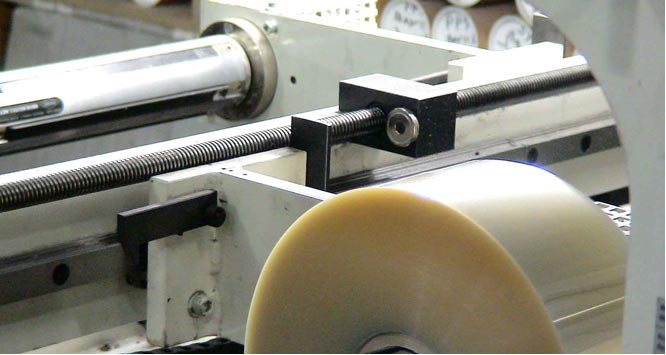

Nick runs a packaging company and bought an F4MA32 (3/8 in. dia x 5/16 in. thick x 3/16 in. hole Neodymium Pot Magnet) from us to use on his window packaging machine.

The machine holds a window film reel that weighs around 44lbs and is loaded onto a roller. The roller is then pushed onto the magnet and from there the position of the film can be adjusted sideways. This small magnet now plays a pivotal part in Nick’s manufacturing process.